It can be learned from the "Modern Chinese Dictionary" that contemporary "hardware" generally refers to gold, silver, copper, iron, and tin (aluminum), these five kinds of metal utensils that are common and commonly used in our lives material.

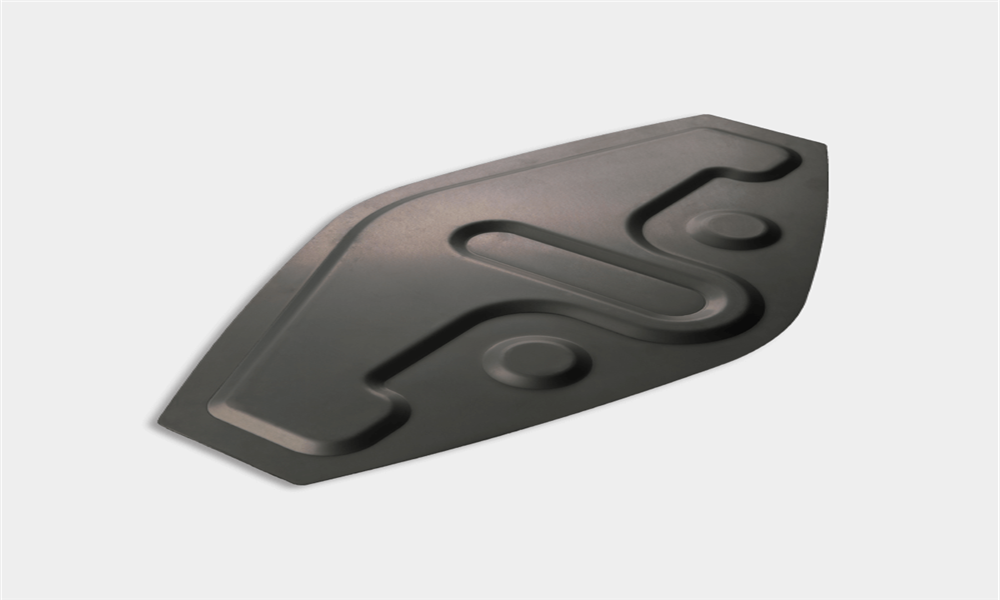

Generally, these materials need to be processed by cutting, forging, calendering, etc. before they become metal utensils, and the final products are collectively referred to as hardware products.

At present, the application of hardware products is very extensive, such as construction hardware, kitchen and bathroom hardware, repair tool hardware, and so on. Hardware includes manual, electric, auto maintenance tools, and other products, and people naturally refer to all products made of metal as hardware.

Common household hardware includes a vise, screwdriver, wrench, hammer, tape measure, electric pen, etc.

The hardware industry also plays a very important role in the development of the national economy and is an important part of my country's light industry. The data shows the future development direction of the hardware industry in 2022, and high-quality development will be the major development of the hardware industry for a long time in the future. trend, general direction.

The "14th Five-Year Development Guidance for the Hardware Industry" was officially released on March 3. It is pointed out that the current hardware product industry is in a critical period of growth momentum transformation, and the guiding ideology, principles, and key tasks to follow for the industry's "14th Five-Year Plan" industry development are clarified, and it is proposed that the average annual growth of the industry's total output value during the "14th Five-Year Plan" period will reach 5 % or more, while further consolidating the status of the global hardware manufacturing factory, the development goal of improving the modern manufacturing system and striding forward to a strong hardware manufacturing country.

Today, the demand for hardware products in my country is 106.87 billion yuan, a year-on-year increase of 2.8%. Driven by the growth of downstream demand, the output of my country's hardware products industry has continued to increase, and the scale of output value has also continued to expand. The output value of the hardware product industry is 163.62 billion yuan, a year-on-year increase of 0.5%. In recent years, the export of hardware products in my country has maintained a stable growth trend. my country has become one of the major exporters of hardware products in the world. It is expected that the annual export value will maintain a growth rate of 10-15% in the future.

Further reading: Process Characteristics of Metal Stamping Parts

Feng-Yu is a China custom metal stamping manufacturer that was founded in 1971, based on our mastery of precision hardware processing technology and nearly 50 years of experience. Hardware processing provides key components for many industrial equipment and products, such as processing hardware stamping parts, injection molding parts, automotive stamping parts, precision hardware stamping parts, medical devices stamping, and other products. Our company provides a one-stop service process from drawing receiving to sample delivery, with stable quality and commitment, please contact us.

In the world of manufacturing and engineering, where precision reigns supreme, every component contributes to the final product's functionality, safety, and efficiency. Often overlooked yet essential, precision metal shims play a vital role.

In the world of electronics, power supply units (PSUs) play a critical role in converting electrical energy, ensuring devices receive the correct voltage and current for optimal operation. To safeguard their components and manage heat, PSUs require durable and efficient enclosures. This is where metal stamped power supply shells excel.

Custom-stamped appliance components are the backbone of products we rely on daily, from refrigerators to washing machines. To ensure appliances work efficiently and safely, these components must be manufactured to precise specifications. This involves challenges such as ensuring accurate dimensions and choosing materials with the right properties for each part.