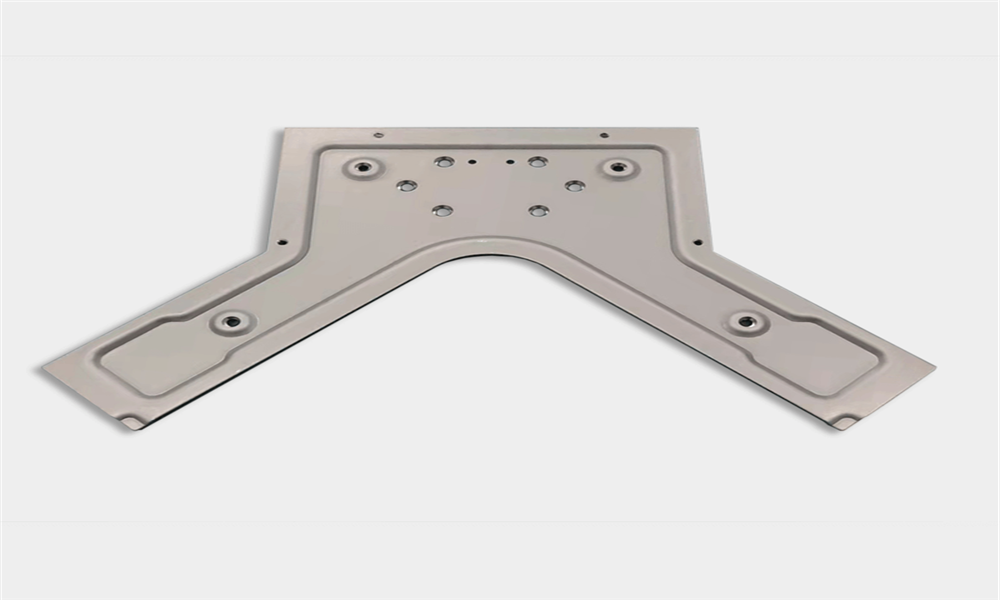

The following describes the characteristics of metal stamping parts processing:

-

High production efficiency.

The number of parts or process content completed per unit time is several times higher than that of ordinary processing methods, even hundreds of times. Moreover, the metal stamping process can further improve production efficiency by using one mold with multiple pieces and multiple process contents combined processing on a set of molds.

-

The product quality is stable and the interchangeability is good.

The metal stamping die is used to form the product. There are a few factors affecting the change in product quality and the degree of harm is low. Some factors can be corrected by taking appropriate measures so that the quality of the product is controlled within the ideal range, and the stability of the product quality can effectively ensure its interchangeability. Good interchangeability is the basic guarantee for mass production of the assembly line. At the same time, it is also conducive to the maintenance and replacement of products.

-

The high utilization rate of materials.

Through different layout methods, such as cross, oblique, multi-row, mixing, nesting, and even non-waste layout, the utilization rate of materials can be effectively improved and the material cost of products can be reduced.

-

The material does not need to be heated.

Under normal circumstances, the material does not need to be heated during the stamping operation. This can not only save energy, reduce the occupation of heating equipment and space, but also avoid the unstable shape and size of products caused by surface oxidation, burns, and deformation caused by heating. It is also possible to prevent adverse effects on the mold due to temperature rise.

-

The mechanical properties of punching parts are improved.

Affected by the hardening phenomenon of metal stamping, the surface structure of punching parts is tight, the hardness and wear resistance are increased, and the strength and rigidity of punching parts are also improved.

-

Wide range of applications.

There are many products suitable for stamping and forming. It can solve many processing contents that cannot or are difficult to be completed by general machining, especially for the processing and forming of some thin, soft, difficult, strange, micro parts, or parts of non-metallic materials, metal stamping forming is almost only one method of processing and forming.

Further reading: Process Characteristics of Metal Stamping Parts

Feng-Yu is a China custom metal stamping manufacturer that was founded in 1971, based on our mastery of precision hardware processing technology and nearly 50 years of experience. Hardware processing provides key components for many industrial equipment and products, such as processing hardware stamping parts, injection molding parts, automotive stamping parts, precision hardware stamping parts, medical devices stamping, and other products. Our company provides a one-stop service process from drawing receiving to sample delivery, with stable quality and commitment, please contact us.

In the world of manufacturing and engineering, where precision reigns supreme, every component contributes to the final product's functionality, safety, and efficiency. Often overlooked yet essential, precision metal shims play a vital role.

In the world of electronics, power supply units (PSUs) play a critical role in converting electrical energy, ensuring devices receive the correct voltage and current for optimal operation. To safeguard their components and manage heat, PSUs require durable and efficient enclosures. This is where metal stamped power supply shells excel.

Custom-stamped appliance components are the backbone of products we rely on daily, from refrigerators to washing machines. To ensure appliances work efficiently and safely, these components must be manufactured to precise specifications. This involves challenges such as ensuring accurate dimensions and choosing materials with the right properties for each part.