Metal stamping is a process used to fabricate parts from sheet metal by pressing the metal into the desired shape using a stamping press. It is usually used to create the outer casing or shell of the motor. In the case of the motor housing, the motor housing serves several important functions, including protecting the internal components of the motor from external damage and providing a mounting point for the motor.

Using metal stamping to fabricate the motor housing offers several advantages over other manufacturing processes, such as casting or machining. One of the main advantages is cost-effectiveness. Metal stamping allows for the production of large quantities of parts at a relatively low cost, making it an attractive option for mass production. In addition, metal stamping allows for the production of precise and accurate parts with consistent quality. The process is also relatively fast, making it an efficient option for high-volume production.

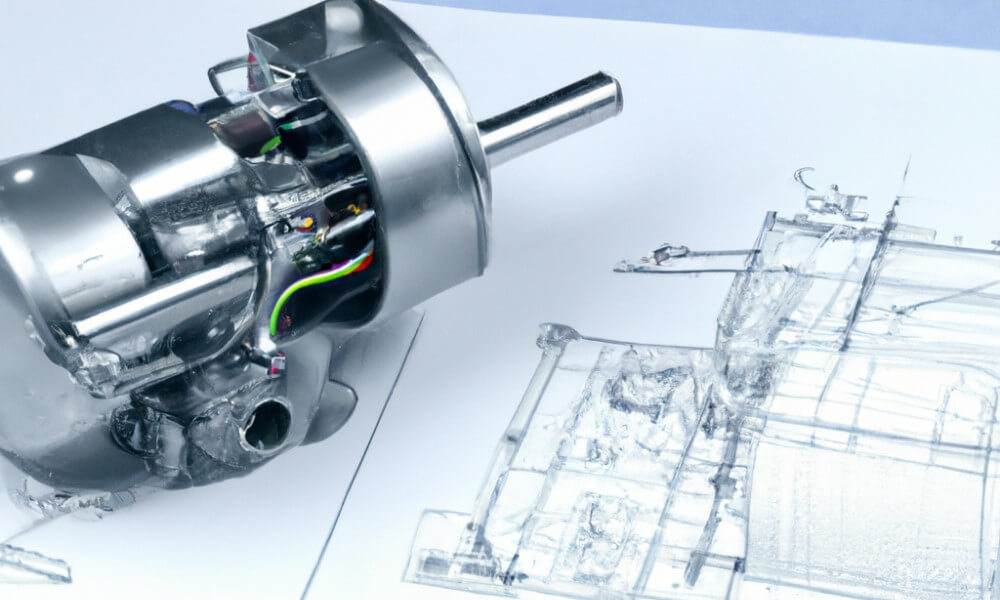

Composition of Electronics Motor

A motor is a device that converts electrical energy into mechanical energy. It consists of several different components that work together to produce rotational motion. The main components of a motor include:

- Stator: The stator is the stationary part of the motor that provides a stationary magnetic field. It consists of a series of electromagnets arranged around the perimeter of a cylinder, which are connected to a power source.

- Rotor: The rotor is the rotating part of the motor that is mounted on a shaft that extends through the center of the stator. It consists of a series of conductors, such as wire coils or permanent magnets, that are mounted on a core or a hub.

- Bearings: Bearings are used to support the shaft and allow it to rotate freely. They may be ball bearings, roller bearings, or another type of bearing, depending on the specific application.

- Housing: The housing is the outer casing of the motor that encloses and protects the internal components. It is typically made of metal, such as aluminum or cast iron, and may be painted or coated to protect against corrosion.

- Terminals: Terminals are used to connect the motor to a power source and to control the speed and direction of the motor. They may be terminals for wire connections or connectors for plugs.

- Cooling system: Many motors have a cooling system, such as a fan or a heat sink, to dissipate the heat generated by the electrical resistance of the winding wire and the mechanical friction of the moving parts. This helps to prevent overheating and extend the life of the motor.

Video of Metal Stamping - Motor Stator

Video of Metal Stamping - Motor Housing Upper

Video of Metal Stamping - Motor Heat Sink

Feng-Yu Precision Electronics Co., Ltd. is a China custom metal stamping manufacturer that was founded in 1971, based on our mastery of precision hardware processing technology and nearly 50 years of experience. Hardware processing provides key components for many industrial equipment and products, such as processing hardware stamping parts, injection molding parts, automotive stamping parts, precision hardware stamping parts, medical devices stamping, and other products. Our company provides a one-stop service process from drawing receiving to sample delivery, with stable quality and commitment, please contact us.

Metal stamping is essential for motor core manufacturing , providing precise shaping, high-volume production, and quality control measures.

Metal stamping is essential for manufacturing pressure stabilizing gaskets, providing precise shaping, high-volume production, and quality control measures.

Metal stamping is crucial for producing stable, precisely positioned brackets in car audio systems. It offers cost-effective, high-quality manufacturing and adapts to advancements, including new materials, automation, and sustainability. Contact us for your precision metal stamping needs.