1. The chemical composition of the material

Generally speaking, the lower the carbon content of steel, the lower the impurity content, the better the plasticity, and the lower the hardness.

2. Material surface quality

The materials of precision shrapnel stamping parts are mostly steel plates, and thin plates are commonly used. There are certain regulations and requirements for the surface quality of steel plates. The surface of the material is smooth, free of scratches, impurities, pores, and shrinkage holes; the cross-section of the material is free of delamination, and the mechanical properties are not significantly damaged; the surface of the material should be free of rust, oxide scale and other attachments. In the stamping process, the material with good surface quality can obtain a smooth surface and high-quality stamping parts, but it is not easy to break and damage the mold during the deformation process.

3. Microstructure

The mechanical properties of metallic materials depend not only on their chemical composition but also on their microstructure. Generally speaking, the microstructure of the metal is very fine, but the plasticity is very large, which is beneficial to the deformation of the material during the stamping process. However, if the microstructure of the metal is too fine, the strength and hardness of the material increase.

4. Thickness tolerance

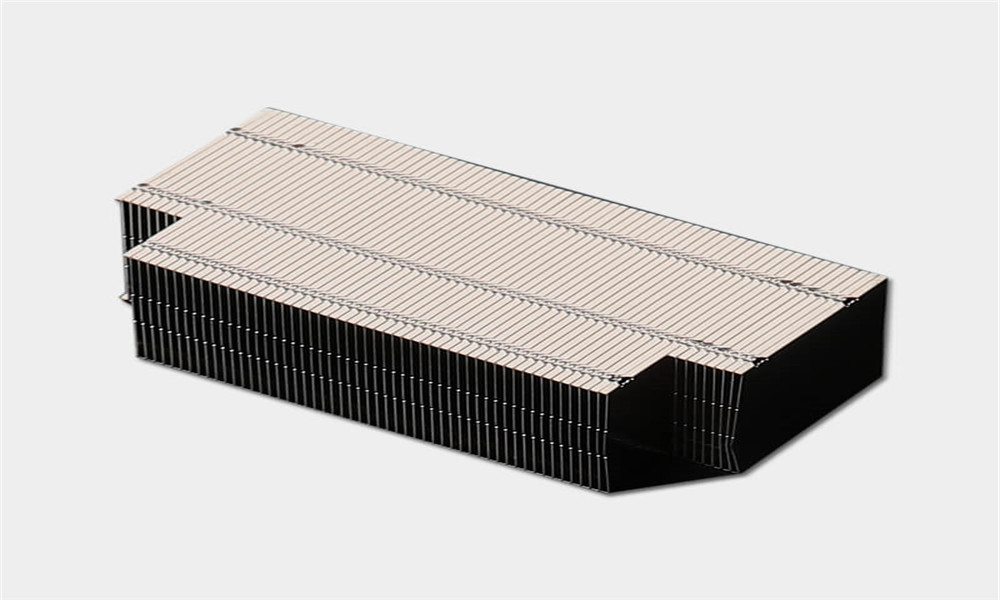

In the process of precision shrapnel stamping, the requirements for thickness tolerance are relatively strict. During the stamping and forming process, there will be high pressure and even parts damage.

Further reading: The reason of precision influence of precision metal stamping parts

Feng-Yu is a China custom metal stamping manufacturer that was founded in 1971, based on our mastery of precision hardware processing technology and nearly 50 years of experience. Hardware processing provides key components for many industrial equipment and products, such as processing hardware stamping parts, injection molding parts, automotive stamping parts, precision hardware stamping parts, medical devices stamping, and other products. Our company provides a one-stop service process from drawing receiving to sample delivery, with stable quality and commitment, please contact us.

In the world of manufacturing and engineering, where precision reigns supreme, every component contributes to the final product's functionality, safety, and efficiency. Often overlooked yet essential, precision metal shims play a vital role.

In the world of electronics, power supply units (PSUs) play a critical role in converting electrical energy, ensuring devices receive the correct voltage and current for optimal operation. To safeguard their components and manage heat, PSUs require durable and efficient enclosures. This is where metal stamped power supply shells excel.

Custom-stamped appliance components are the backbone of products we rely on daily, from refrigerators to washing machines. To ensure appliances work efficiently and safely, these components must be manufactured to precise specifications. This involves challenges such as ensuring accurate dimensions and choosing materials with the right properties for each part.