The wide application of metal stamping parts should be beyond our imagination, and it will be involved in almost every field of life. However, when you use this kind of metal stamping parts, you will always encounter some problems. No matter what the reason is, these faults of metal stamping parts must be solved in time.

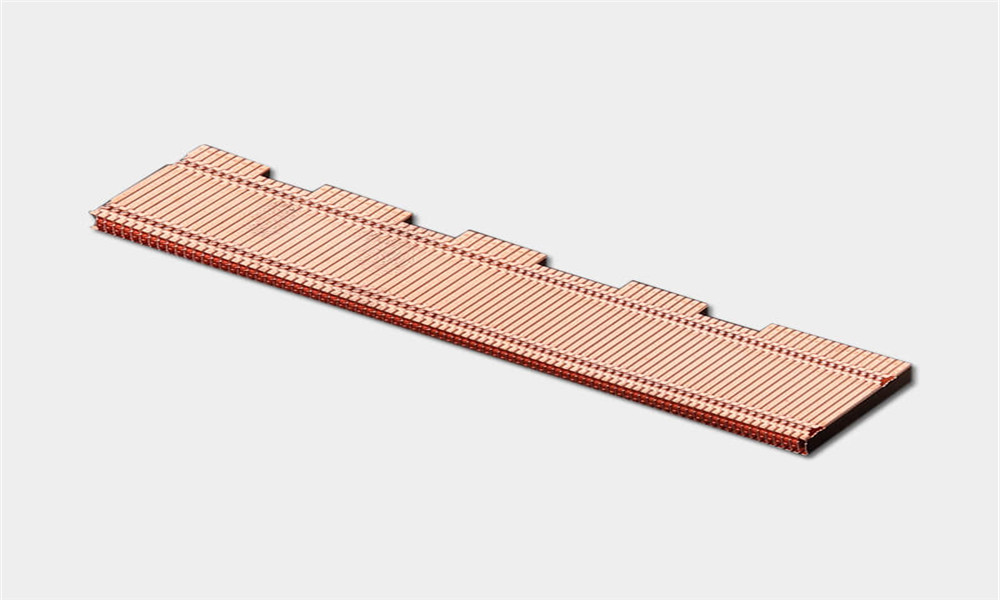

In case of poor processing of metal stamping parts, the conventional method is to first determine the deformation compensation amount according to the material, product structure, etc.; then design the mold according to the compensation amount to stamp out the finished or semi-finished product, and further process the semi-finished product to the finished product. The more common bad phenomena on metal stamping parts include cracks, wrinkles, strains, uneven thickness, non-forming, and other tapping and thread processing.

A little carelessness in the stamping process will cause various defects, such as cracking of metal stamping parts. When metal stamping parts are affected by internal stress, external impact, or environmental conditions, cracks will occur on their surface or inside.

This kind of cracking phenomenon usually occurs in the rounded parts of metal stamping parts, and the thickness of the cracked parts becomes very thin. In order to prevent cracking, the structure, forming process, and mold design of metal stamping parts should be analyzed from many aspects, and corresponding measures should be taken.

To improve the structure of metal stamping parts, it is required that the radius of each fillet be as large as possible, the actual depth of the surface shape in the drawing direction is shallower, the depth is uniform everywhere, and the shape is as simple as possible and the change is as gentle as possible, etc., to reduce cracking possibility.

From the perspective of the drawing process, the drawing direction of metal stamping parts should make the contact area between the punch and the blank as large as possible, and the reasonable shape of the blank holder and blank holder force make the resistance of each part of the blank holder even and moderate and reduce the drawing. Depth, open process holes, process cuts, etc.

Further reading: Cracking of metal stamping parts

Feng-Yu is a China custom metal stamping manufacturer that was founded in 1971, based on our mastery of precision hardware processing technology and nearly 50 years of experience. Hardware processing provides key components for many industrial equipment and products, such as processing hardware stamping parts, injection molding parts, automotive stamping parts, precision hardware stamping parts, medical devices stamping, and other products. Our company provides a one-stop service process from drawing receiving to sample delivery, with stable quality and commitment, please contact us.

In the world of manufacturing and engineering, where precision reigns supreme, every component contributes to the final product's functionality, safety, and efficiency. Often overlooked yet essential, precision metal shims play a vital role.

In the world of electronics, power supply units (PSUs) play a critical role in converting electrical energy, ensuring devices receive the correct voltage and current for optimal operation. To safeguard their components and manage heat, PSUs require durable and efficient enclosures. This is where metal stamped power supply shells excel.

Custom-stamped appliance components are the backbone of products we rely on daily, from refrigerators to washing machines. To ensure appliances work efficiently and safely, these components must be manufactured to precise specifications. This involves challenges such as ensuring accurate dimensions and choosing materials with the right properties for each part.