In recent years, although China's metal stamping processing industry has developed a lot, it lags far behind the development of the machine tool industry. According to data, China's current annual sales of metal stamping parts are 10 billion yuan, of which the share of metal stamping hard tools is less than 25%. with a growing need.

At present, the imbalance of the metal stamping processing structure is the wrong way of production and demand. For example, the metal stamping processing required by users is very large, but the high-speed steel metal stamping processing is overproduced. There is a huge shortage of much-needed parts in modern manufacturing, but there is an overproduction of low-grade parts. To the technical development trend of the machinery manufacturing industry, the proportion of CNC machine tools in Chinese factories will increase year by year, and the demand for parts will increase rapidly, while the demand for traditional standard parts will decrease year by year.

China is a major producer and exporter of metal stamping. Among the power tools sold in the world, most of them are produced and exported from China. China has become the world's leading supplier of power tools. Although China's metal stamping industry has a large scale, many metal stamping production companies usually lack core competitiveness, and are difficult to grow bigger and stronger due to factors such as weak technical innovation ability, too single market structure, and weak brand influence.

Further reading: Process Characteristics of Metal Stamping Parts

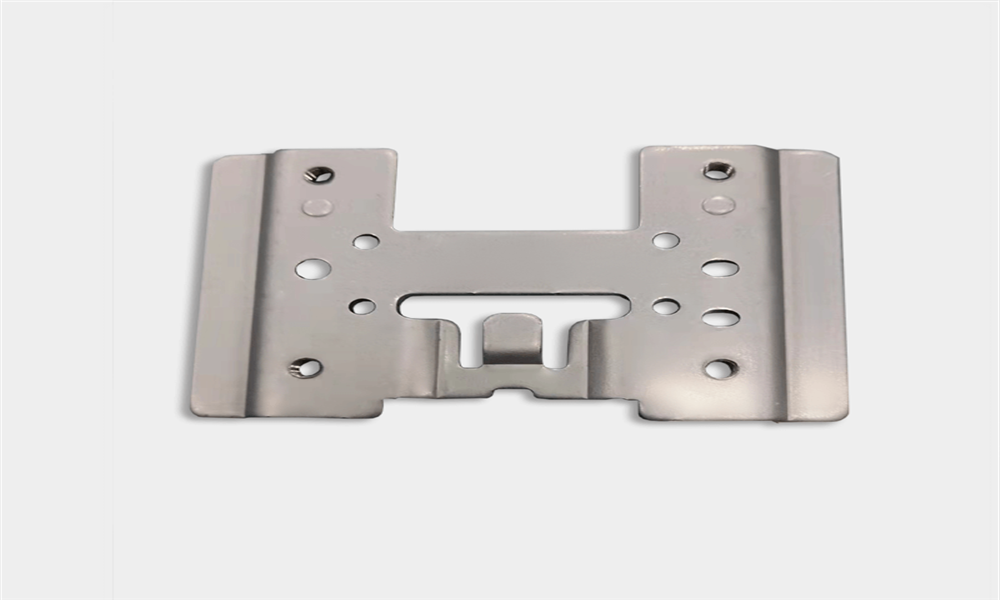

Feng-Yu is a China custom metal stamping manufacturer that was founded in 1971, based on our mastery of precision hardware processing technology and nearly 50 years of experience. Hardware processing provides key components for many industrial equipment and products, such as processing hardware stamping parts, injection molding parts, automotive stamping parts, precision hardware stamping parts, medical devices stamping, and other products. Our company provides a one-stop service process from drawing receiving to sample delivery, with stable quality and commitment, please contact us.

In the world of manufacturing and engineering, where precision reigns supreme, every component contributes to the final product's functionality, safety, and efficiency. Often overlooked yet essential, precision metal shims play a vital role.

In the world of electronics, power supply units (PSUs) play a critical role in converting electrical energy, ensuring devices receive the correct voltage and current for optimal operation. To safeguard their components and manage heat, PSUs require durable and efficient enclosures. This is where metal stamped power supply shells excel.

Custom-stamped appliance components are the backbone of products we rely on daily, from refrigerators to washing machines. To ensure appliances work efficiently and safely, these components must be manufactured to precise specifications. This involves challenges such as ensuring accurate dimensions and choosing materials with the right properties for each part.