The automotive manufacturing industry is continuously evolving, adapting to new technological advancements and customer demands. In this blog post, we'll delve into the intricacies of automotive metal stamping and discuss its association with precision — a crucial factor in producing quality parts for the industry..

What is Precision Metal Stamping?

Precision metal stamping is a specialized manufacturing technique that utilizes complex dies and advanced machinery to create superior quality metal parts with commendable precision. High-quality materials are fed into machines, manipulated, and finally transformed into end products. Precision metal stamping is ideal for maintaining consistency and accuracy over large production volumes, thus ensuring outstanding results in automotive manufacturing.

The Role of Precision Metal Stamping in the Automotive Industry

Precision metal stamping plays a crucial role in the modern automotive industry, driven by the increasing technical demands and rigorous quality standards for automotive metal stamping parts. Our expertise in precision metal stamping enables us to provide a wide range of high-quality components for automotive manufacturers, as illustrated by the following examples:

-

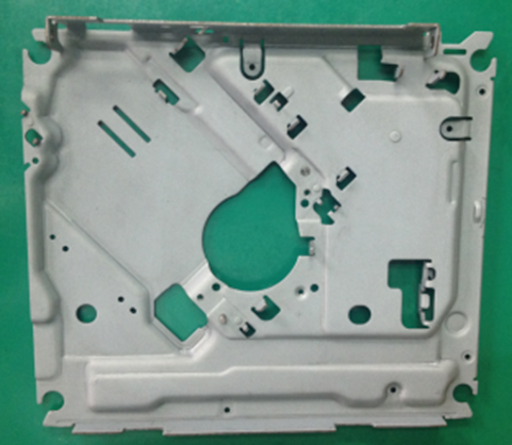

Clutch Cooling System : We produce durable and lightweight cooling system components that meet stringent thermal management requirements.

-

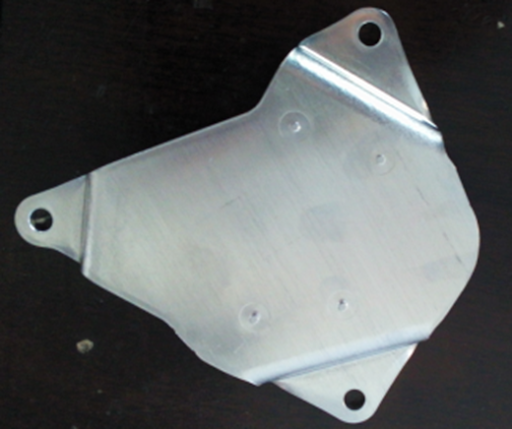

Stereo Mounting Bracket : We offer precise and reliable brackets for secure and stable stereo installation.

-

Transmission Mount : Our robust transmission mounts ensure optimal vibration dampening and engine performance.

Furthermore, our extensive experience extends to a diverse range of automotive applications, including :

- Radiator Frames

- Brake Components

- Seating Components

- Transmission Components

- Brackets

- EV Battery Components

- EV Charging Components

- Chassis Components and Frames

- Engine Parts and Accessories

- Interior and Exterior Fittings and Trim

Faced with the ever-evolving complexity and diversity of automotive components, precision metal stamping proves to be a reliable and versatile method for manufacturers to create the highest quality parts. Our commitment to innovation and continuous improvement ensures that we remain at the forefront of this critical technology.

Advantages of Precision Automotive Metal Stamping

Precision metal stamping comes with numerous benefits, making it indispensable to the automotive industry:

- Cost-effectiveness : The capability of precision metal stamping to produce large volumes of high-quality components at reduced costs makes it highly economical for automotive manufacturers.

- Speed and efficiency : A faster production process enables manufacturers to enhance efficiency and reduce lead times.

- Scalability : Precision metal stamping accommodates both small and large production volumes, catering to diverse needs.

- Precision and accuracy : The impressive precision and strict tolerances achieved through this process are vital for the perfect fit and functionality of automotive parts.

Case Study: Precision Metal Stamping Application

As a premier Precision Metal Stamping service provider, we assisted a top automotive manufacturer in adopting precision metal stamping to produce engine components for their high-performance sports car. These components required intricate design details and strict tolerance levels, which were impeccably achieved through precision metal stamping. As a result, the company ensured the delivery of superior quality cars that garnered rave reviews from both critics and consumers.

Further reading : Precision Metal Stamping for Other Applications

Frequently Asked Questions About Precision Metal Stamping for Automotive

1.What materials are used in precision metal stamping?

Common materials include steel, aluminum, brass, copper, and various alloys, depending on specific requirements.

2.Can precision metal stamping accommodate small production volumes?

Yes, it is well-suited for both small and large production runs, making it highly versatile.

3.How can I ensure high-quality products from precision metal stamping?

Work with providers who have a proven track record, certified processes, and a commitment to quality control.

Partner with Feng Yu for Your Automotive Metal Stamping Projects

With over 50 years of experience, Feng Yu has perfected its skills in automotive metal stamping. Our commitment to quality and innovation, combined with a profound understanding of the automotive industry's requirements, empowers us to deliver excellence in every project. We have assisted numerous clients in streamlining their production processes and enhancing the quality of their output through our precision-focused automotive metal stamping process.

If you need assistance with precision metal stamping or have questions about the process, feel free to reach out to us. Our experts are here to address your concerns and help turn your automotive manufacturing aspirations into reality. Contact us today!

In the world of manufacturing and engineering, where precision reigns supreme, every component contributes to the final product's functionality, safety, and efficiency. Often overlooked yet essential, precision metal shims play a vital role.

In the world of electronics, power supply units (PSUs) play a critical role in converting electrical energy, ensuring devices receive the correct voltage and current for optimal operation. To safeguard their components and manage heat, PSUs require durable and efficient enclosures. This is where metal stamped power supply shells excel.

Custom-stamped appliance components are the backbone of products we rely on daily, from refrigerators to washing machines. To ensure appliances work efficiently and safely, these components must be manufactured to precise specifications. This involves challenges such as ensuring accurate dimensions and choosing materials with the right properties for each part.