News

We are actively pursuing better development of precision stamping parts. If you want to know the latest news of Feng Yu, please follow us.

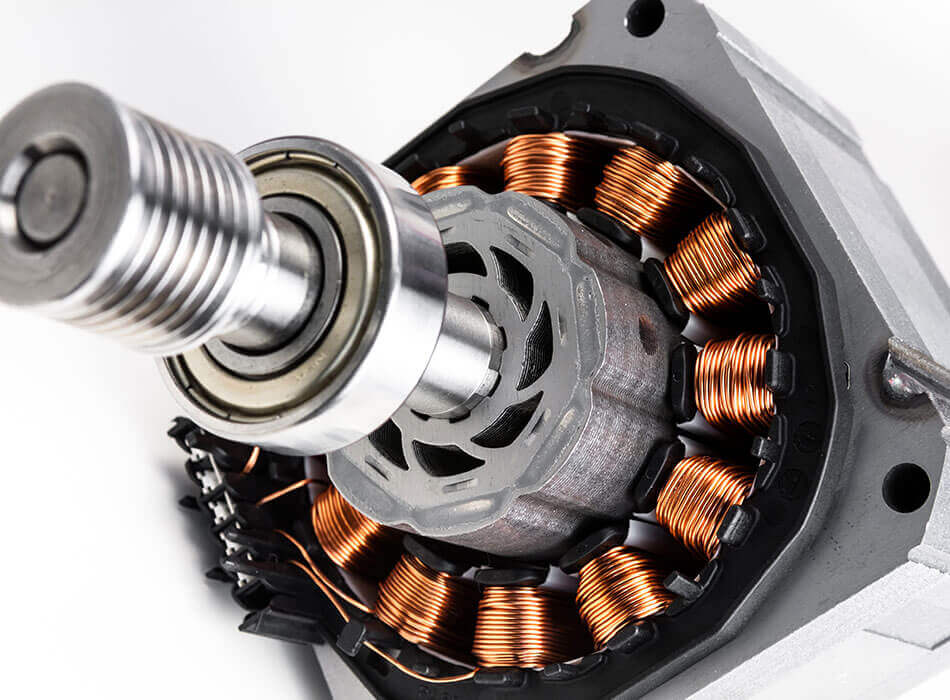

Metal stamping is essential for motor core manufacturing , providing precise shaping, high-volume production, and quality control measures.

Metal stamping is essential for manufacturing pressure stabilizing gaskets, providing precise shaping, high-volume production, and quality control measures.

Metal stamping is crucial for producing stable, precisely positioned brackets in car audio systems. It offers cost-effective, high-quality manufacturing and adapts to advancements, including new materials, automation, and sustainability. Contact us for your precision metal stamping needs.

Learn what is copper components continuous metal stamping manufacturing, and discover its benefits, including high efficiency, cost-effectiveness, and high precision.

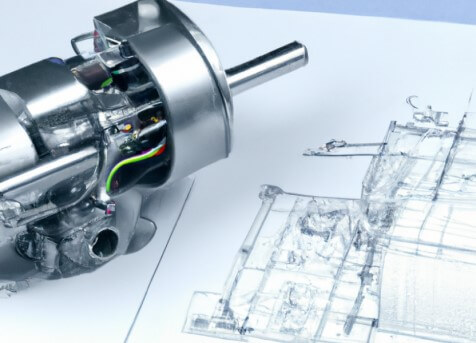

Learn why metal stamping is the ideal solution for motor manufacturing, and discover how this process improves motor efficiency, durability, and cost-effectiveness.

Discover the intricate process of metal stamping and how it is used to create solar panel fixing brackets. Learn about the tools and techniques used in the art of metal stamping and how they contribute to the production of high-quality solar panel fixtures.

When stamping the magnetic levitation sheet of a magnetic levitation fan motor, there are several key factors that should be considered to ensure proper performance and longevity of the fan.

Many parts of a digital camera can be made using stamping, including the camera body and various internal components such as brackets and holders. Stamping can be used to form metal parts to precise dimensions, making it a useful manufacturing process for a wide variety of camera components.

Using metal stamping to fabricate the motor housing offers the main advantage is cost-effectiveness over other manufacturing processes, such as casting or machining.