News

We are actively pursuing better development of precision stamping parts. If you want to know the latest news of Feng Yu, please follow us.

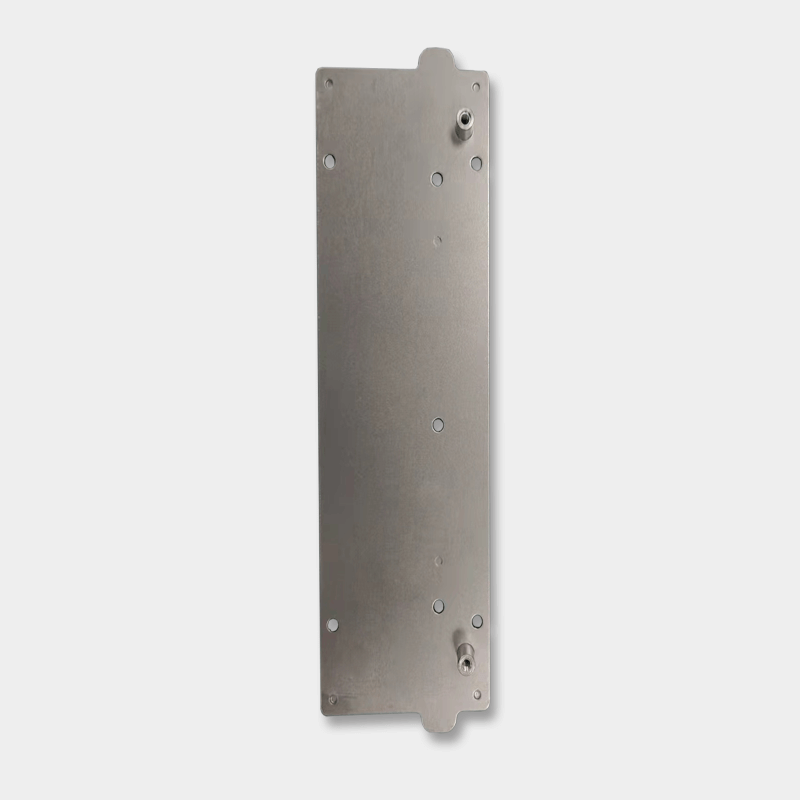

In the world of manufacturing and engineering, where precision reigns supreme, every component contributes to the final product's functionality, safety, and efficiency. Often overlooked yet essential, precision metal shims play a vital role.

In the world of electronics, power supply units (PSUs) play a critical role in converting electrical energy, ensuring devices receive the correct voltage and current for optimal operation. To safeguard their components and manage heat, PSUs require durable and efficient enclosures. This is where metal stamped power supply shells excel.

Custom-stamped appliance components are the backbone of products we rely on daily, from refrigerators to washing machines. To ensure appliances work efficiently and safely, these components must be manufactured to precise specifications. This involves challenges such as ensuring accurate dimensions and choosing materials with the right properties for each part.

The furniture industry relies heavily on precision metal stamped parts due to their strength, durability, and cost advantages.

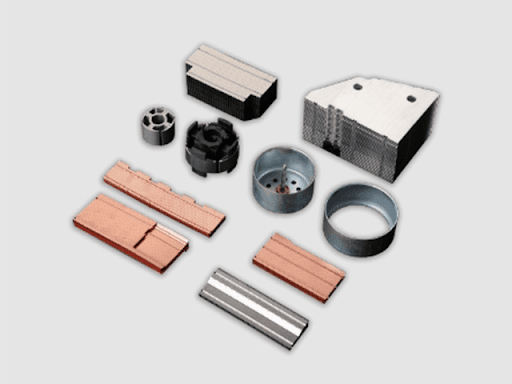

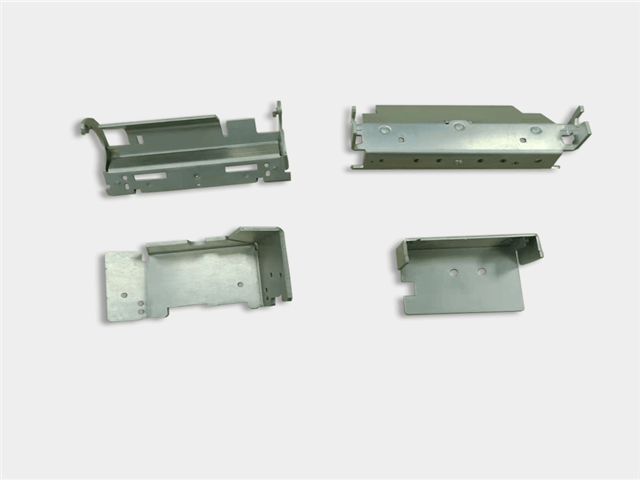

Precision metal stamping is a versatile manufacturing process used to create a wide range of metal parts for various industries, including automotive, electronics, aerospace, and medical.

precision is the pivotal factor in every element of aerospace design. One method standing out as an epitome of precision is Aerospace Metal Stamping. This technique, specializing in Precision Metal Stamping, enables the creation of intricate, high-performing parts with an admirable degree of precision, revolutionizing the aerospace industry.

Welcome to the continuation of our exploration into the challenges of metal stamping miniature components. In "Part 2," we unravel the final two hurdles, providing a comprehensive overview of this demanding industry.

The challenges associated with metal stamping small parts can vary depending on the specific requirements and characteristics of the parts involved.

This guide aims to demystify the complexities of the automotive metal stamping process, providing concise insights into core concepts and stamping operations within the precision metal stamping domain.

The automotive manufacturing industry is continuously evolving, adapting to new technological advancements and customer demands. In this blog post, we'll delve into the intricacies of automotive metal stamping and discuss its association with precision — a crucial factor in producing quality parts for the industry..

Feng Yu is a leading provider of custom sheet metal stamping services. We offer a wide range of capabilities and can meet your specific needs.

Aluminum stamping plays a pivotal role in modern manufacturing, offering a precise and efficient method for crafting intricate components.

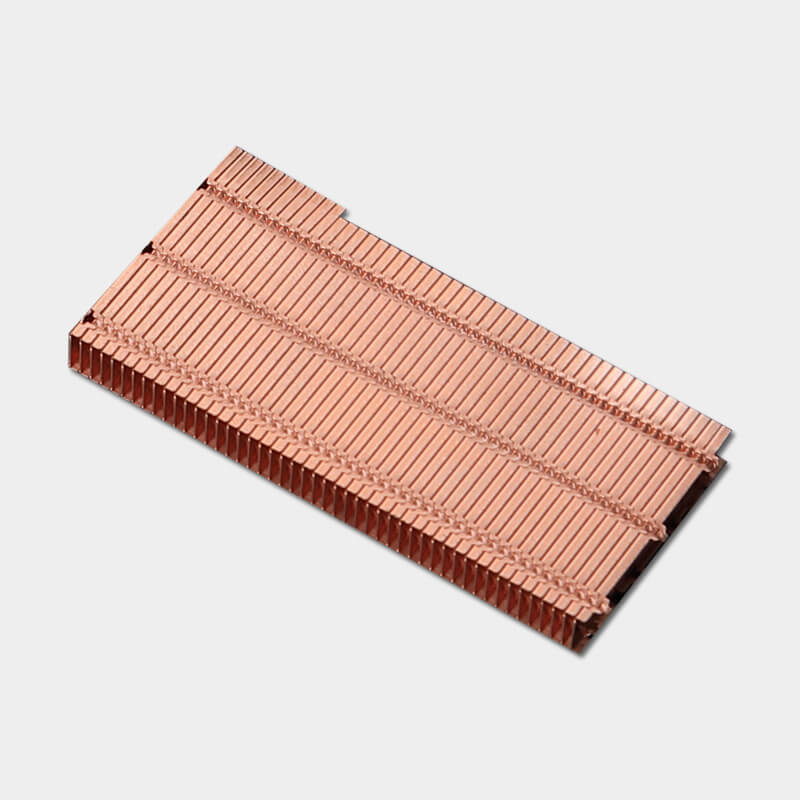

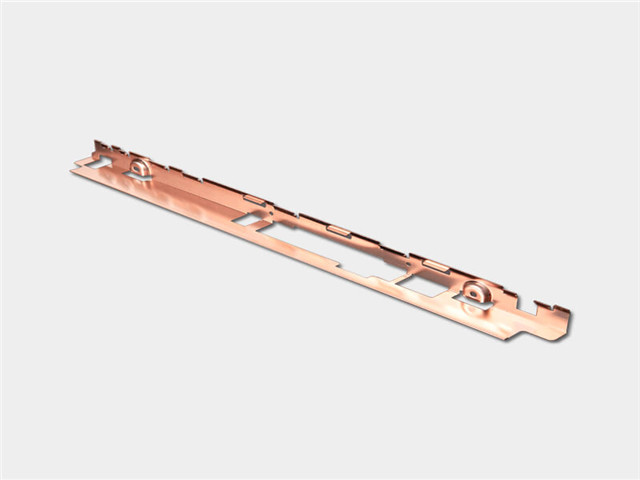

Metal stamping is a versatile and efficient manufacturing process that finds applications in various industries. In this article, we will explore the world of metal stamping, specifically focusing on the production of copper stamping parts.

Deep draw metal stamping is a sophisticated manufacturing process that enables the creation of intricate and complex metal components. This article delves into the world of deep draw metal stamping, exploring its process, materials, applications, advantages, and much more.

Explore the significance of metal stamping in the context of car parts manufacturing. We will discuss the materials used, the metal stamping process, quality control measures, and the advantages of employing metal stamping techniques in the automotive sector.

Discover the world of automotive stamping and its applications. Learn how to manufacturing flawless car lamp and gain insights into the innovative processes involved.

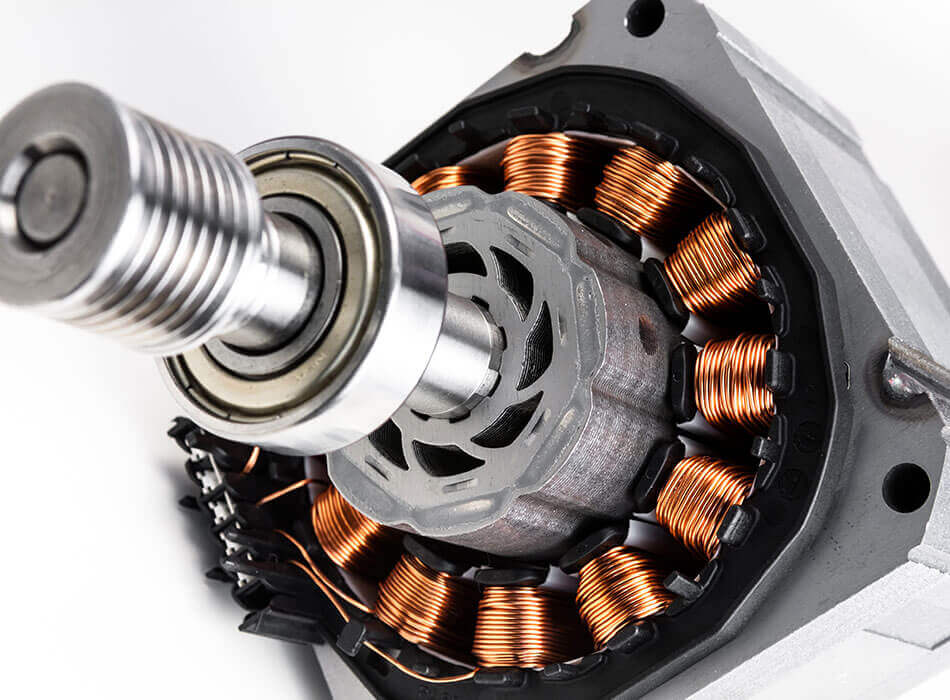

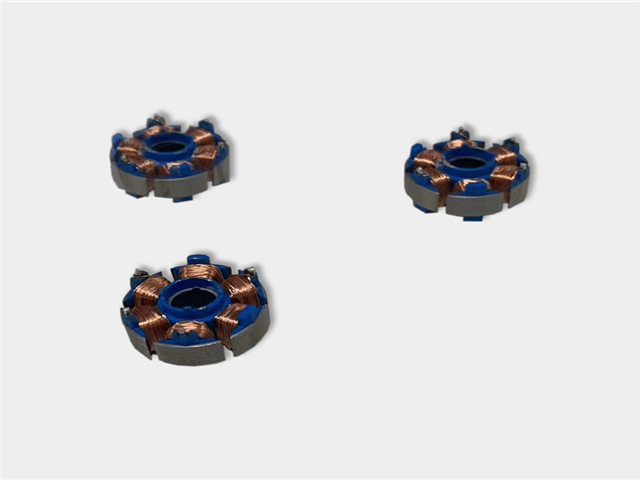

Metal stamping is essential for motor core manufacturing , providing precise shaping, high-volume production, and quality control measures.

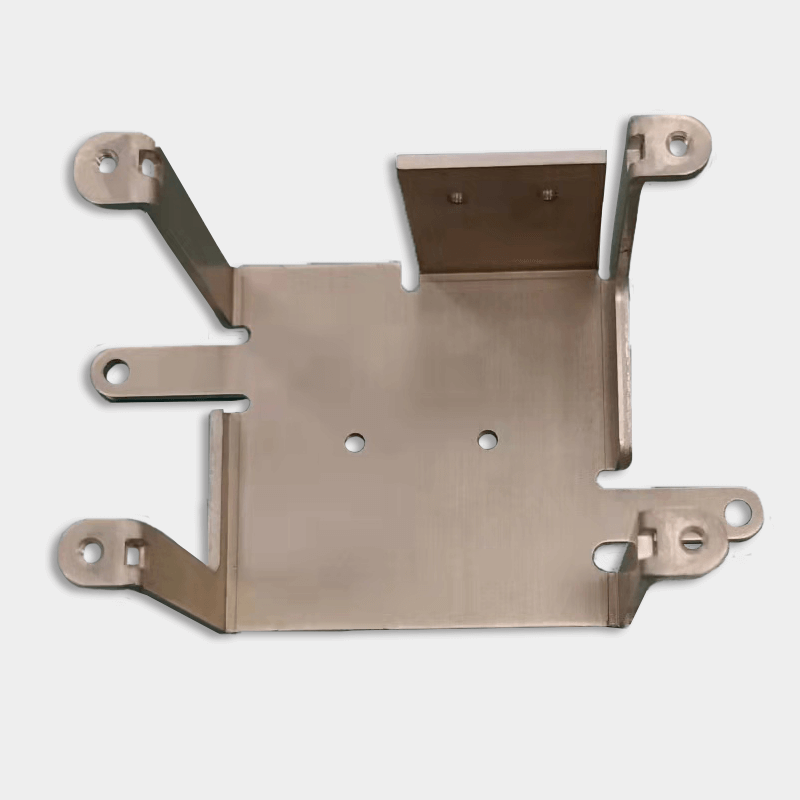

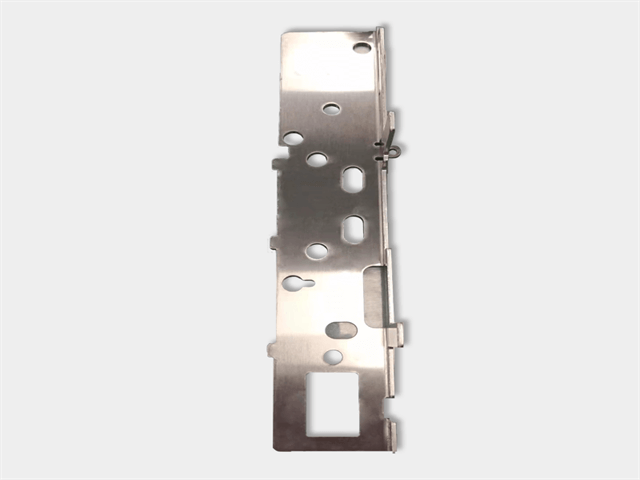

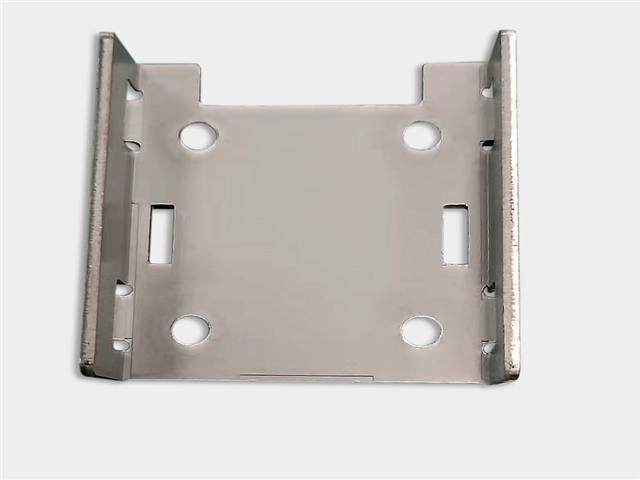

Discover the world of bracket stamping and its applications. Learn how to manufacturing flawless brackets and gain insights into the innovative processes involved.

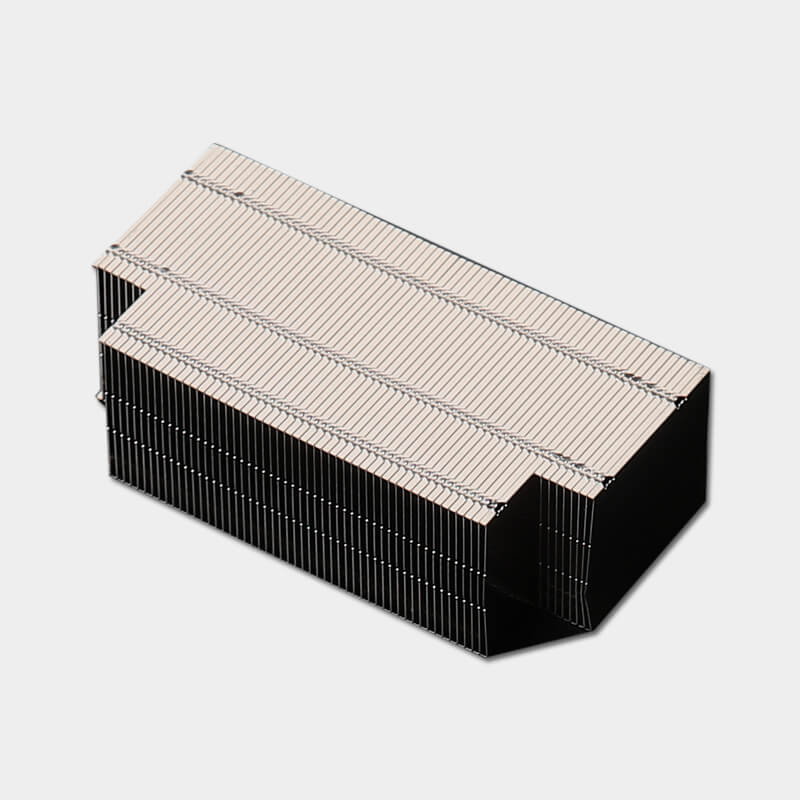

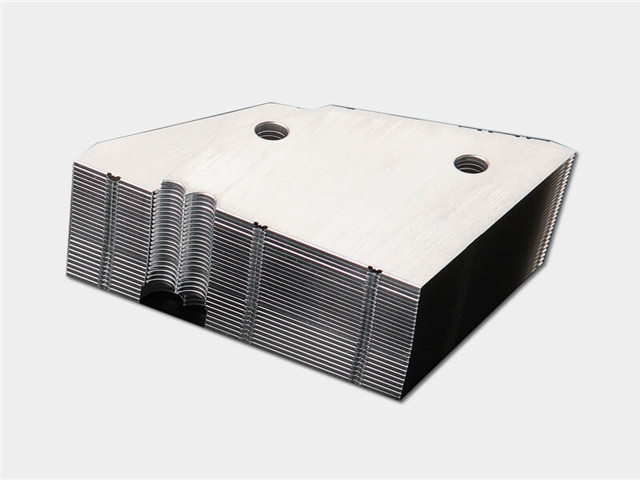

A stamping heat sink, also known as a stamped heat sink, is a specialized cooling component used in electronic devices to dissipate heat generated by electronic components such as processors, transistors, and integrated circuits.

Sheet metal stamping is a widely used manufacturing process in the production of metal components for various industries.

Metal stamping is essential for manufacturing pressure stabilizing gaskets, providing precise shaping, high-volume production, and quality control measures.

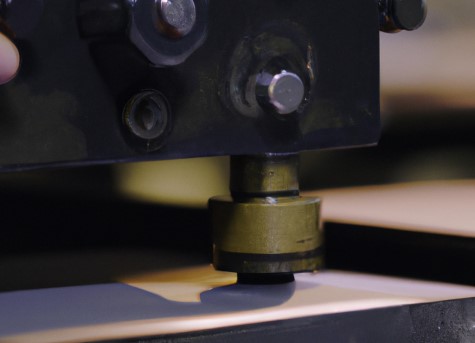

Metal stamping processing involves precise bending and minimizing spring back. Factors like punch and die gaps, fillet radii, and bending depth are crucial.

Metal stamping is crucial for producing stable, precisely positioned brackets in car audio systems. It offers cost-effective, high-quality manufacturing and adapts to advancements, including new materials, automation, and sustainability. Contact us for your precision metal stamping needs.

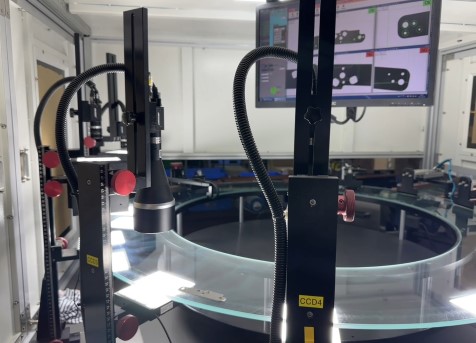

Automated visual industrial quality control systems let Feng-yu produce high-precision stamping parts that meet the demanding requirements of a range of industries.

Metal stamping is an efficient, cost-effective method for mass-producing high-quality parts with complex shapes, standard designs, and high accuracy.

Metal stamping parts offer precision, efficiency, consistency, versatility, high material utilization, and improved mechanical properties, making it ideal for mass production.

Metal stamping produces high-precision metal parts but faces spring back issues. Effective solutions include material selection, die design, and process optimization.

Learn what is copper components continuous metal stamping manufacturing, and discover its benefits, including high efficiency, cost-effectiveness, and high precision.

Learn why metal stamping is the ideal solution for motor manufacturing, and discover how this process improves motor efficiency, durability, and cost-effectiveness.

Discover the intricate process of metal stamping and how it is used to create solar panel fixing brackets. Learn about the tools and techniques used in the art of metal stamping and how they contribute to the production of high-quality solar panel fixtures.

When stamping the magnetic levitation sheet of a magnetic levitation fan motor, there are several key factors that should be considered to ensure proper performance and longevity of the fan.

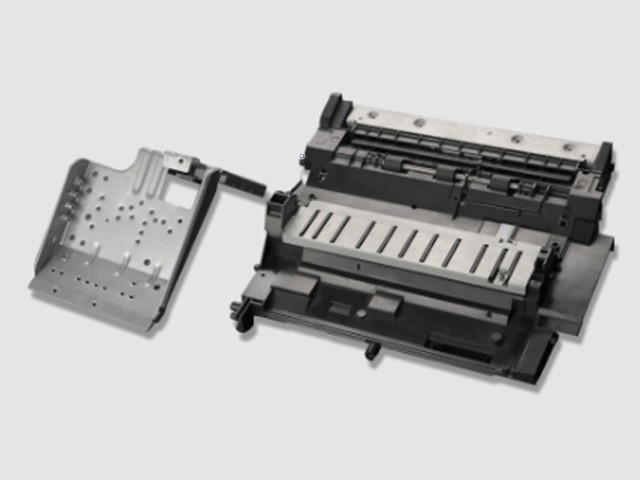

Many parts of a digital camera can be made using stamping, including the camera body and various internal components such as brackets and holders. Stamping can be used to form metal parts to precise dimensions, making it a useful manufacturing process for a wide variety of camera components.

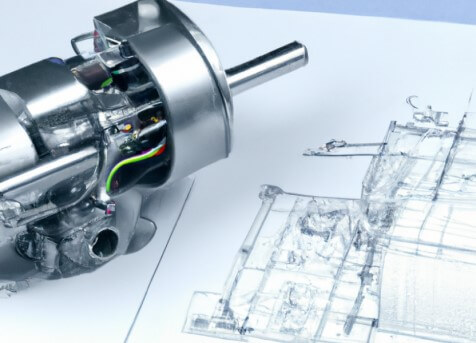

Using metal stamping to fabricate the motor housing offers the main advantage is cost-effectiveness over other manufacturing processes, such as casting or machining.

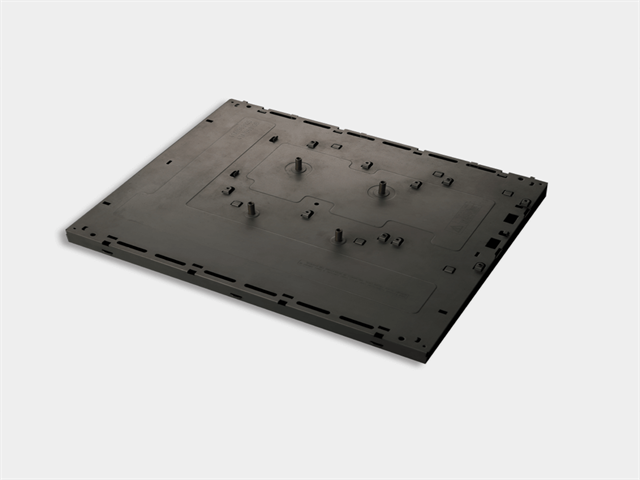

Metal stamping parts are pieces of metal that are shaped by applying an intense force through a die. Metal blanks are inserted into dies and then pressed to create specific shapes. Commonly stamped items include car body panels, engine components, and household appliances.

No matter in terms of operation technology or safety, the metal stamping process should meet the corresponding requirements, starting from its technical measures. You should know that the so-called metal stamping is a process of deforming or breaking iron, aluminum, copper and other plates and dissimilar materials to a certain shape and size by using a punch and a mold.

According to the total deformation properties of materials, hardware processing processes are divided into two categories and five types of deformation in the stamping process.

No matter where the designed and produced stamping parts are used for processing, they need to be designed and processed in strict accordance with the corresponding principles, so as to achieve energy conservation and other purposes on the premise of ensuring product quality.

if there is a slight carelessness in the operation process of stamping, it is easy to cause the metal stamping parts to crack, tear, and other undesirable phenomena, affecting the normal use of the products.

No matter where the designed and produced stamping parts are used for processing, they need to be designed and processed in strict accordance with the corresponding principles, so as to achieve energy conservation and other purposes on the premise of ensuring product quality.

_spic_spic.png)

The quality of metal stamping parts is improving, and the requirements for mold quality and service life are high. The effective way to improve the quality.

Many of the products we use in our lives are made of metal stamping parts, but friends who are engaged in metal stamping parts processing know.

_spic.png)

In fact, the metal stamping parts can be divided into two categories according to different processes, namely separation process and forming process.

_spic.png)

metal stamping dies are the most important technological equipment in the process of metal parts stamping, to prolong the service life and use the effect, it is necessary to do maintenance work on it.

_spic.png)

Metal stamping parts can be divided into two categories according to different processes, namely the separation process and the forming process.

_spic.png)

The characteristics of metal stamping parts processing are high production efficiency, product quality is stable and interchangeability is good, a high utilization rate of materials, the material does not need to be heated, the mechanical properties of punching parts are improved, and a wide range of applications.

_spic.png)

The wide application of metal stamping parts should be beyond our imagination, and it will be involved in almost every field of life. However, when you use this kind of metal stamping parts, you will always encounter some problems. No matter what the reason is, these faults of metal stamping parts must be solved in time.

With the development of hardware products industry, the production equipment and technology of metal stamping parts are constantly improving, and the metal stamping parts are becoming more and more precise. Precision metal stamping parts can be divided into various types according to industry, use and process characteristics.

The processing of precision metal stamping is no longer a fashionable thing. People in the industry know that the process is the same, and it is inseparable from it. However, with the upgrading of technology, its advantages will be greatly improved this time.

With the development of the hardware industry, the production equipment and technology of metal stamping parts are constantly improving, and metal stamping parts are becoming more and more precise.

This article will explain 8 purposes of machining metal stamping parts, including auto parts, electronic parts, home appliance parts, integrated circuit lead frames, Motor cores, electrical iron cores, Heat exchanger fins, and other parts.

The processing of metal stamping parts is a process that uses punches and dies to deform or break stainless steel, iron, aluminum, copper, and other plates and heterosexual materials to achieve a certain shape and size.

It can be learned from the "Modern Chinese Dictionary" that contemporary "hardware" generally refers to gold, silver, copper, iron, and tin (aluminum), these five kinds of metal utensils that are common and commonly used in our lives material.

Precision hardware processing is a process with high requirements in all aspects, but as long as these precautions are followed, it can generally be done well.

The advantages of metal stamping parts and factors affecting the accuracy of precision metal stamping parts.

In recent years, although China's metal stamping processing industry has developed a lot, it lags far behind the development of the machine tool industry. According to data, China's current annual sales of metal stamping parts are 10 billion yuan, of which the share of metal stamping hard tools is less than 25%. with a growing need.

How to adjust the machine during the production of precision metal stamping parts is the first problem that a precision metal stamping terminal factory has to face, and it is also a skill that a precision metal stamping terminal factory needs to master.

The chemical composition of the material, material surface quality, microstructure, and thickness tolerance.

Metal stamping parts are very common metal processing products in life, and they play a very important role. Let's understand the measurement method of metal stamping parts.

With the development of society, metal stamping parts have been applied to all aspects of our daily life. The requirements for stamping parts are constantly improving, and the quality requirements for precision metal stamping parts are also getting higher and higher.

With the improvement of people's living standards, the quality requirements for stamping parts are also getting higher and higher. Stamping parts processing plants should pay attention to understanding customer needs and meeting customer needs, which is the top priority.

In the past, Feng-Yu has been focusing on completing the customer's entrustment, committed to the improvement of processing technology, and accumulated its own strength.