Medical Devices Metal Stamping

With the outbreak of the epidemic, the demand for medical-related equipment is in short supply, and the demand for hardware and spare parts for medical equipment is also rising. This all tests the technology and professionalism of the stamping manufacturer.

Services Beneficial to Medical Industry

We provide comprehensive metal stamping services that have specific capabilities beneficial for Medical devices stamping applications:

- Precision metal stamping

- 3D CAD/CAM

- Mold and die design

- Electroplating

- Electrophoresis

- Dehydrogenation

- Heat treating

Specialty Materials

We have experience working with a wide range of metal stamping materials especially those most often used by the medical industry:

- SAPH440

- A6063: aluminum alloy

- SPCC: cold rolled carbon steel sheet

- Q235: carbon structural steel

- TBA245: container plate material

- Material thickness ranging from 1.0 to 6.0 mm

Advanced Technology

We utilize advanced technology to streamline metal stamping processes and achieve our goal of zero defects:

- More than 150 high-speed precision presses from 25 to 600 ton

- Production management system

- Precision quality testing equipment

- Over 50 years of medical device stamping experience

Quality

We are committed to mistake-proof metal stamping processes and comply with all medical industry standards related to parts production:

- ISO9002:1994

- ISO9001:2008

- IATF 16949:2016

- Three System Certificate

Feng-Yu is a precision stamping service provider and its pursuit of medical device stamping parts, accuracy and fineness exceed the market level, which is one of the reasons why customers trust us.

Related Video

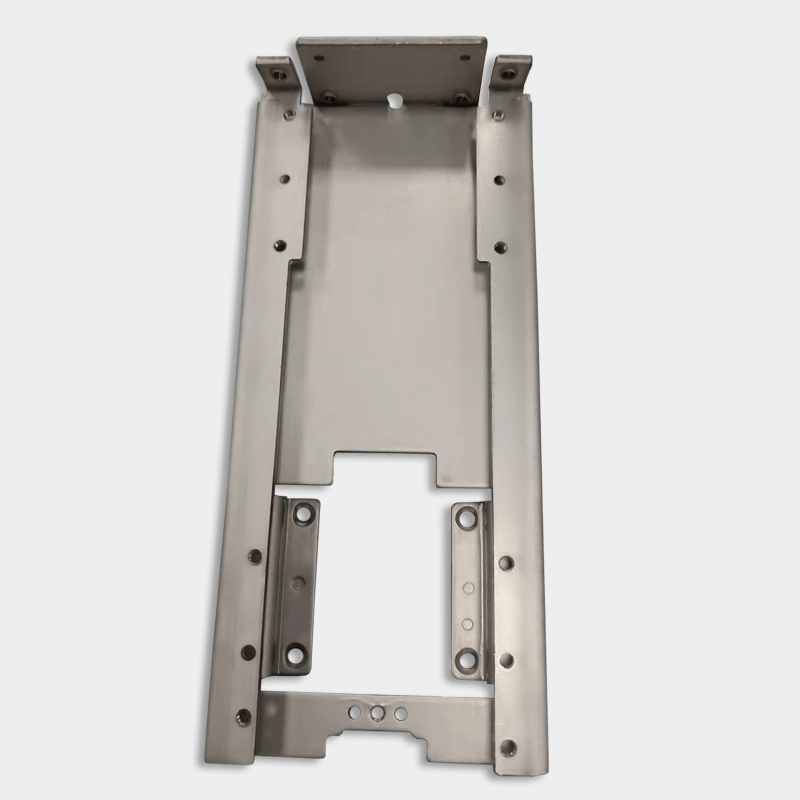

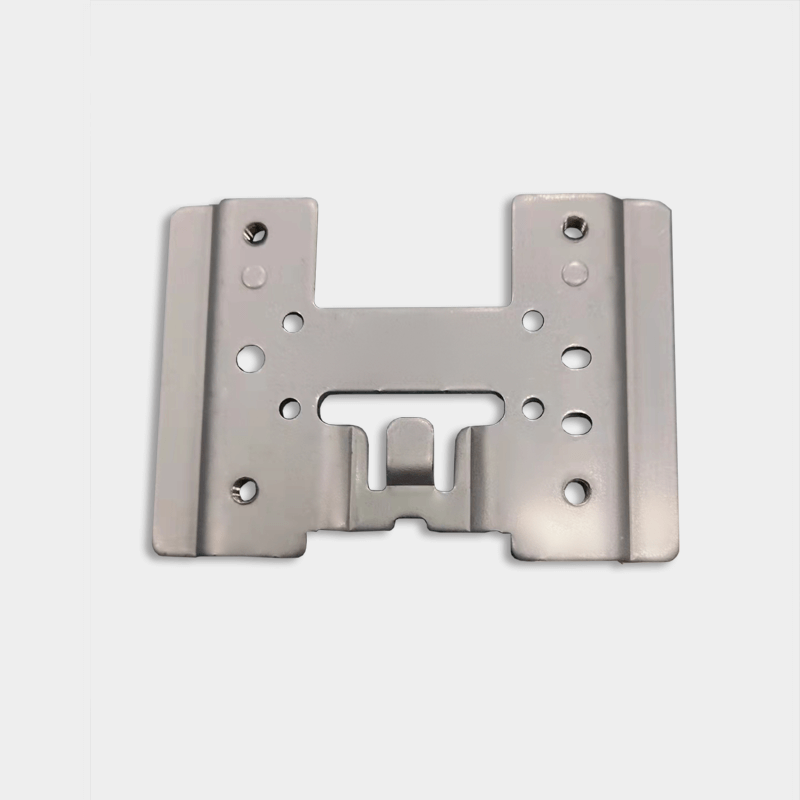

Metal Stamping - Automatic Lifting Bracket Fixing Plate

If you're a medical devices manufacturer in need of metal stamping services, choose Feng Yu Precision Electronics. Since 1971, we have created high-quality components to meet every customer's needs. To learn more about our commitment to quality, contact us today.

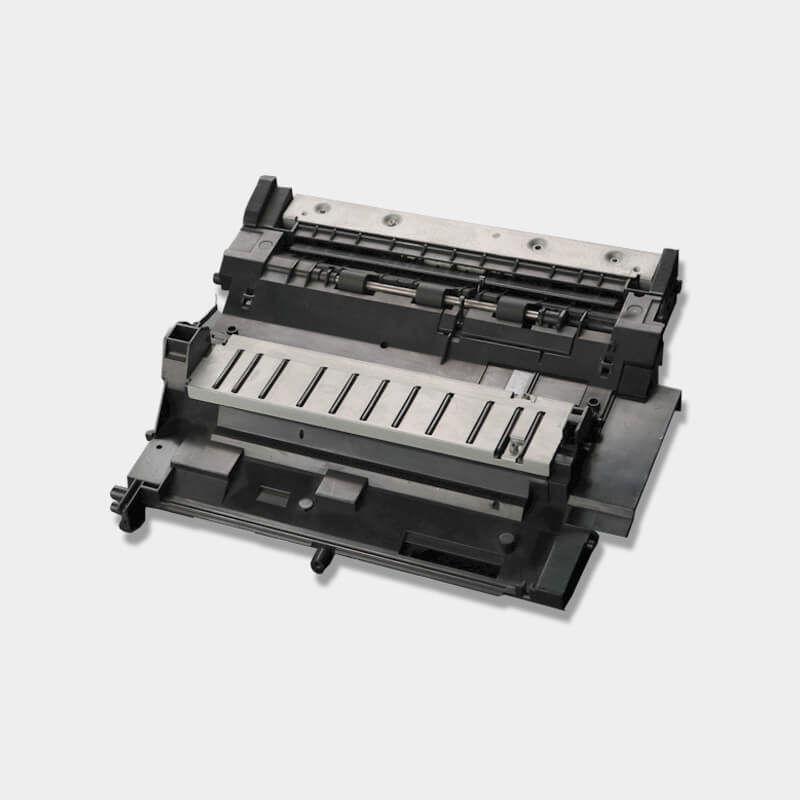

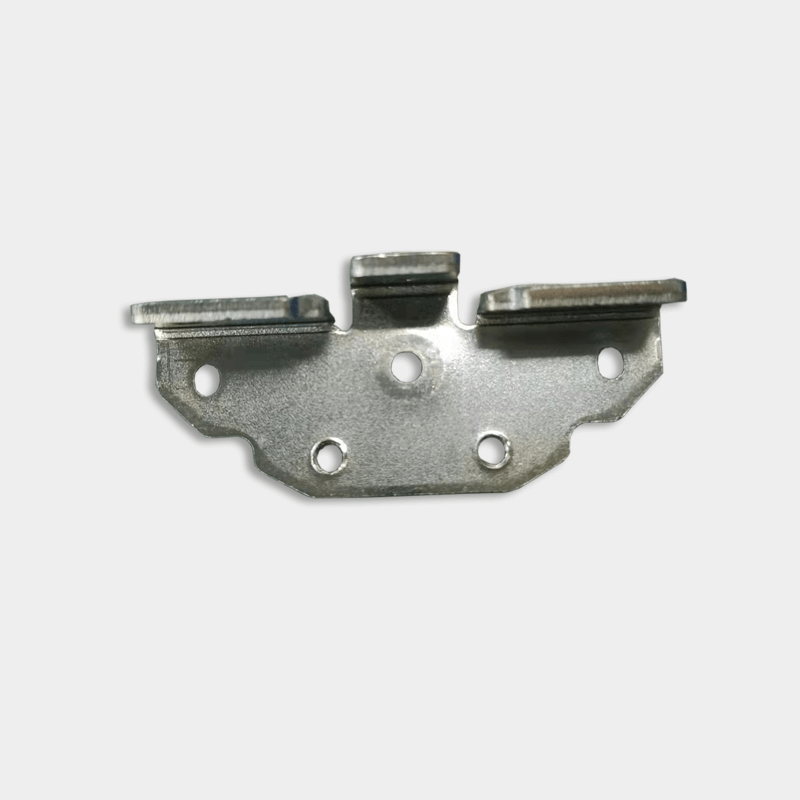

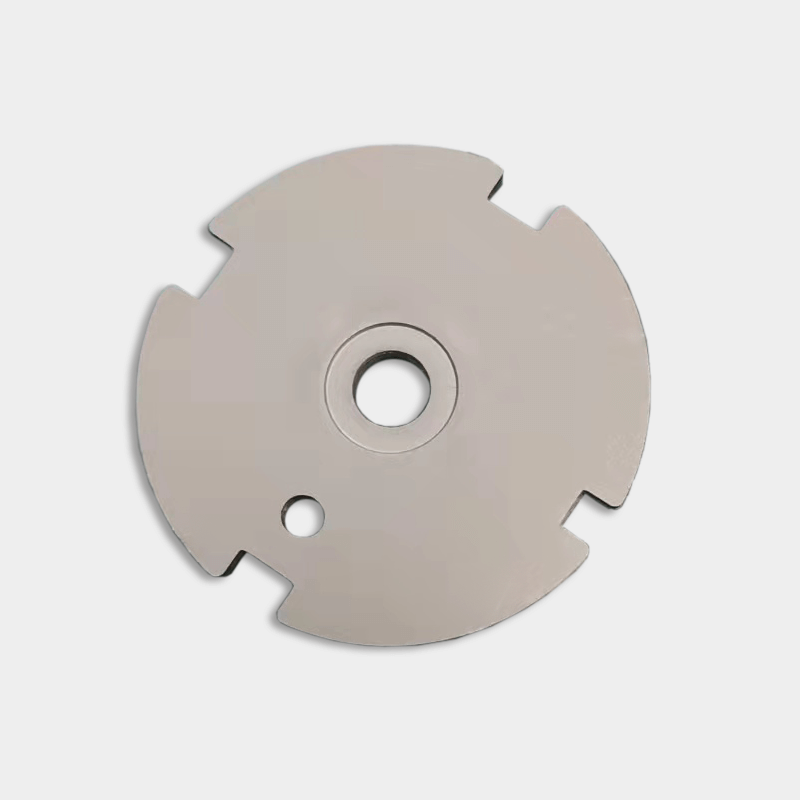

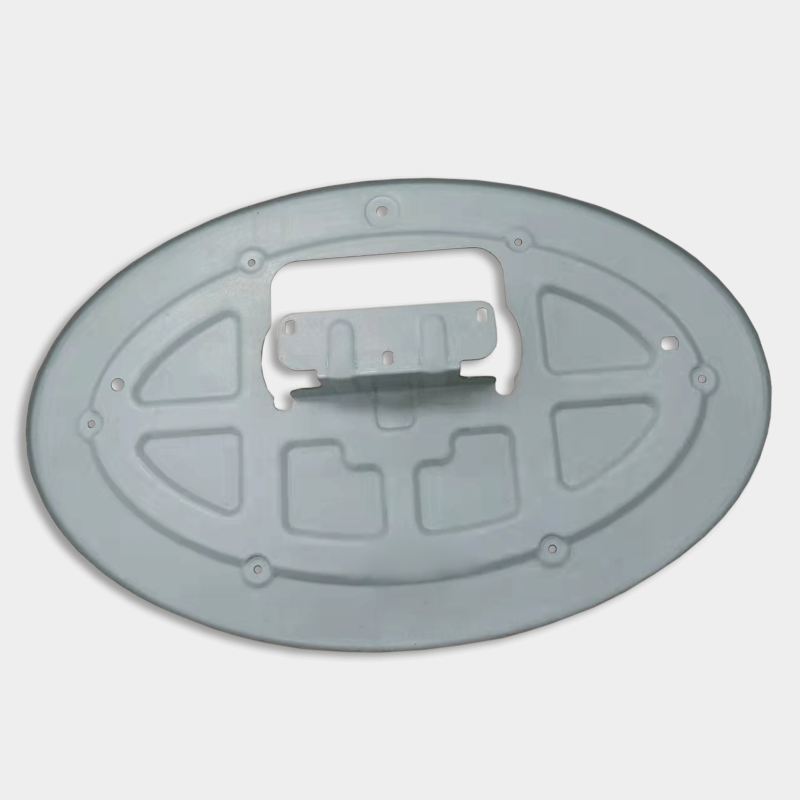

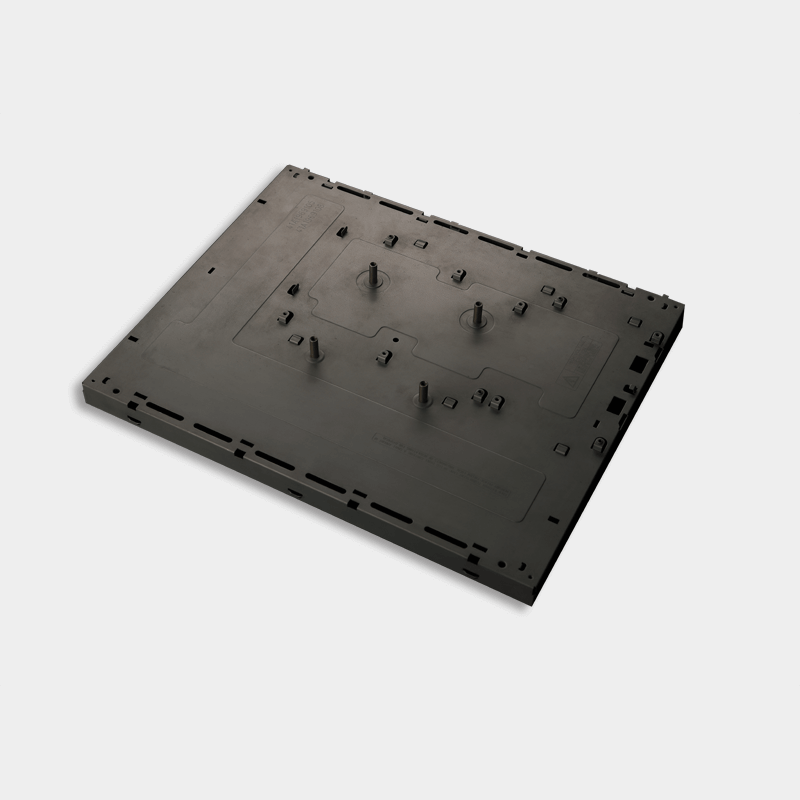

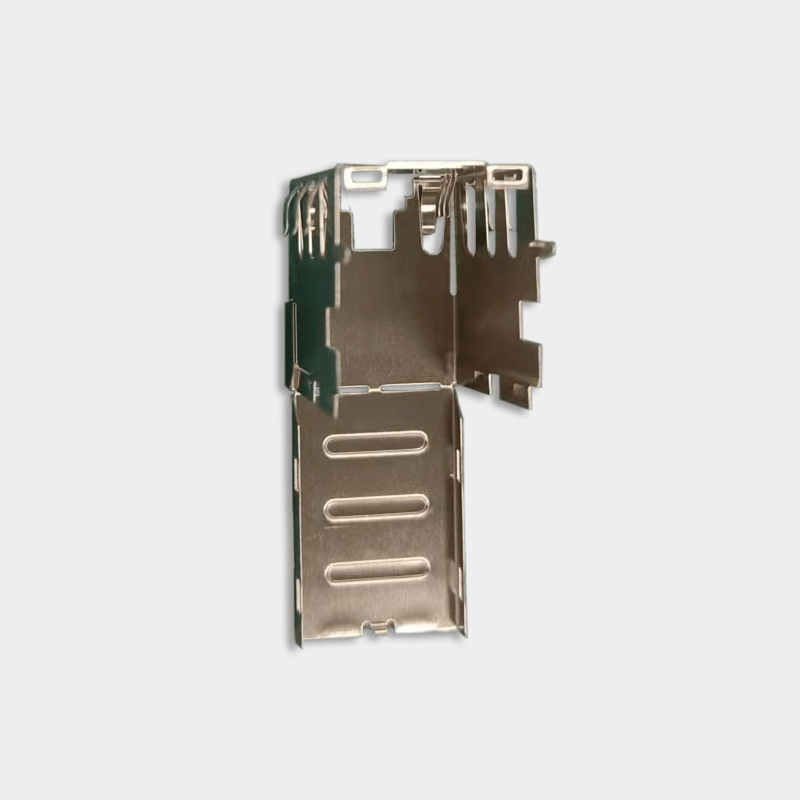

Applied Products