新闻中心

我们积极追求更好的发展,想知道丰钰最新动态请关注我们。

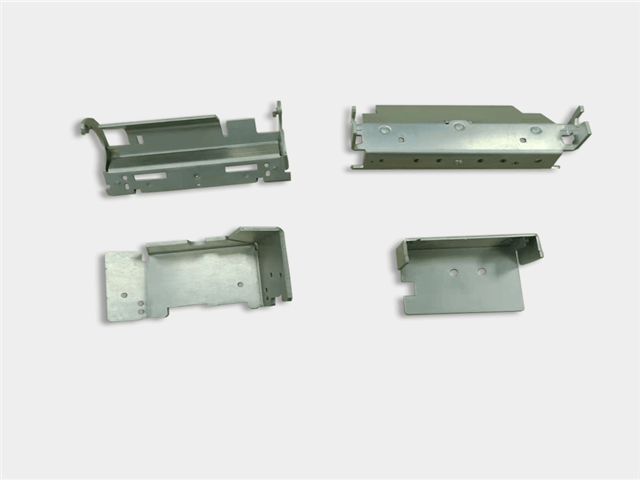

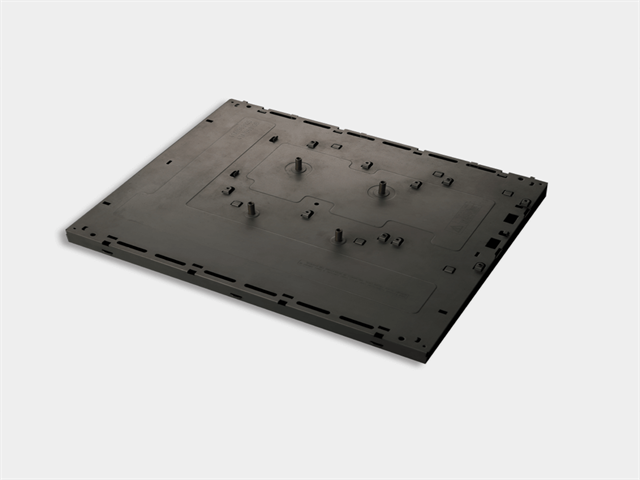

金属冲压对于制造稳压垫圈、提供精确成型、大批量生产和质量控制措施至关重要。

金属冲压加工涉及精确弯曲和最小化回弹。 冲头和模具间隙、圆角半径和弯曲深度等因素至关重要。

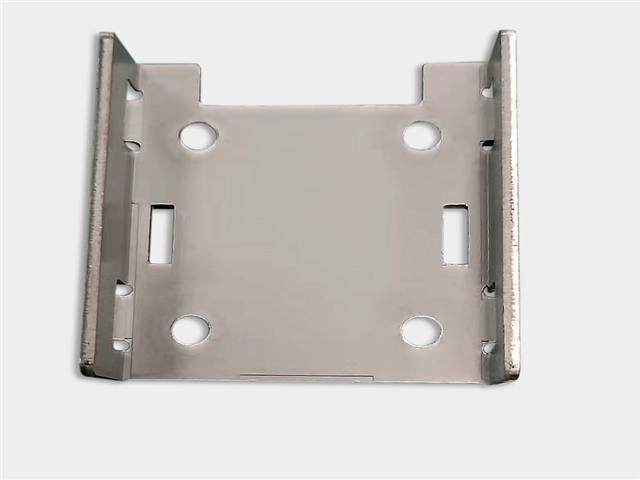

金属冲压在车载音频系统中生产稳定、精确定位的支架方面至关重要。它提供经济高效、高质量的制造,并适应包括新材料、自动化和可持续性在内的技术进步。如有精密金属冲压需求,请与我们联系。

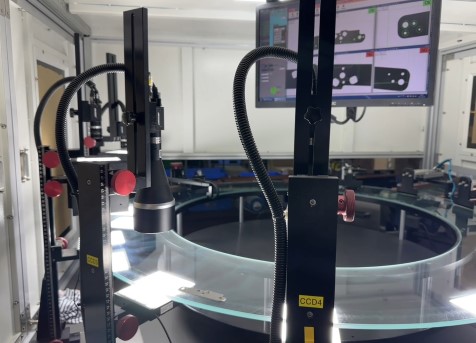

自动化视觉工业品质控制系统使得鳳宇能够生产满足多个行业苛刻要求的高精度冲压零件。

Metal stamping is an efficient, cost-effective method for mass-producing high-quality parts with complex shapes, standard designs, and high accuracy.

Metal stamping parts offer precision, efficiency, consistency, versatility, high material utilization, and improved mechanical properties, making it ideal for mass production.

Metal stamping produces high-precision metal parts but faces spring back issues. Effective solutions include material selection, die design, and process optimization.

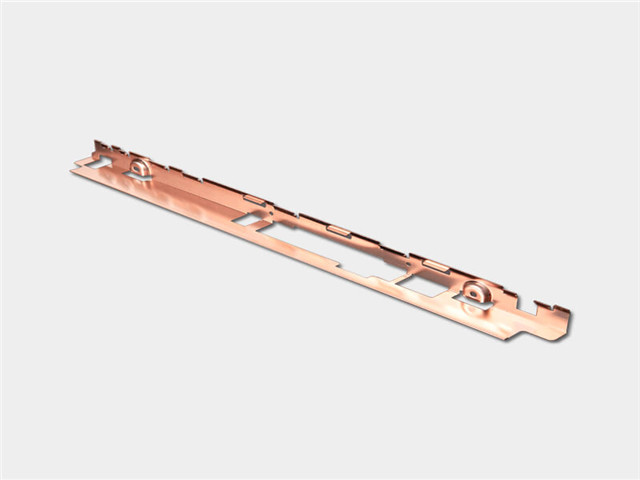

了解什么是铜零部件连续金属冲压制造,以及它的好处,包括高效率、成本效益和高精度。

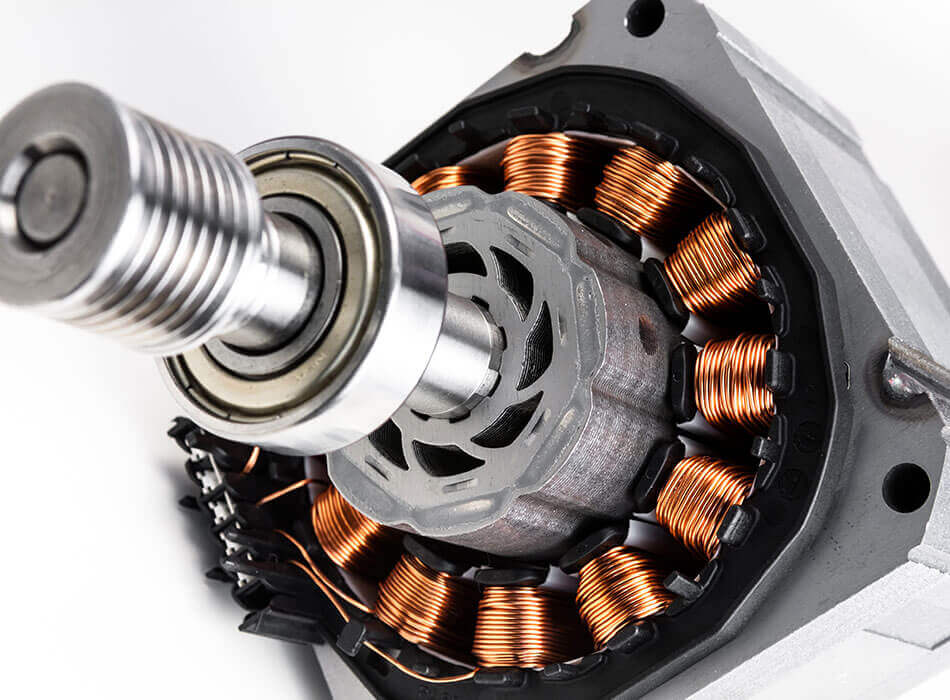

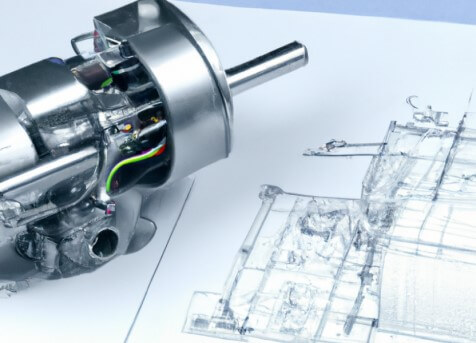

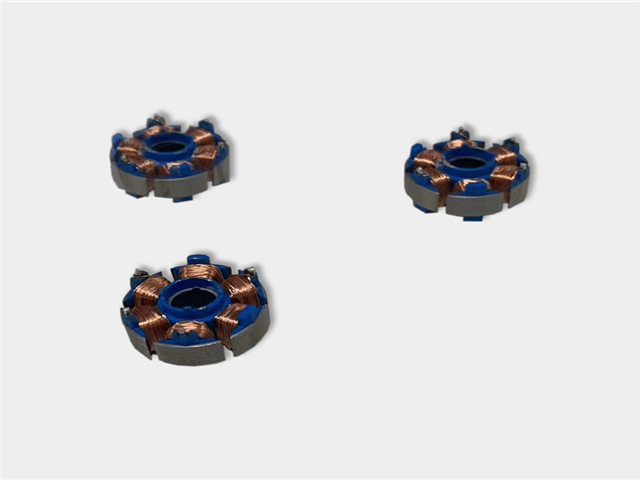

了解为什么金属冲压是电机制造的理想解决方案,探索这个过程如何提高电机的效率、耐久性和成本效益。

探索金屬冲壓的複雜過程以及如何利用它來製造太陽能電池板固定支架。了解金屬冲壓的工具和技術,以及它們如何為生產高品質的太陽能板固定件做出貢獻。

品管人员

熟悉五金冲压行业的生产流程检验方法和各量具的熟练操作,个人性格开朗、态度端正、工作认真负责、能与内外部进行良性沟通。薪资面议职位福利

在冲压磁悬浮风扇电机的磁悬浮片时,应考虑几个关键因素,以确保风扇的良好性能和长寿命。

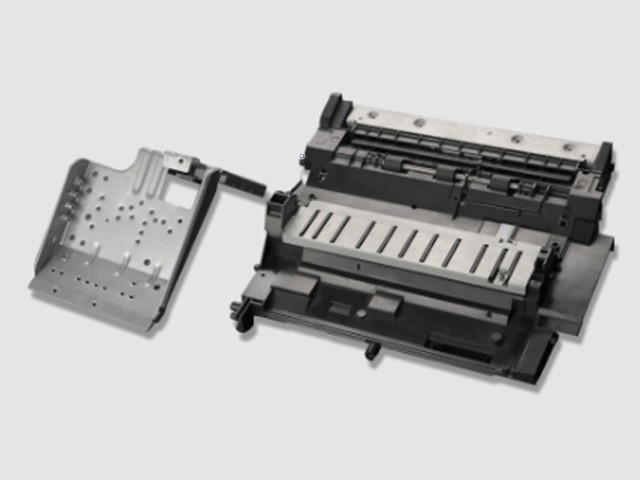

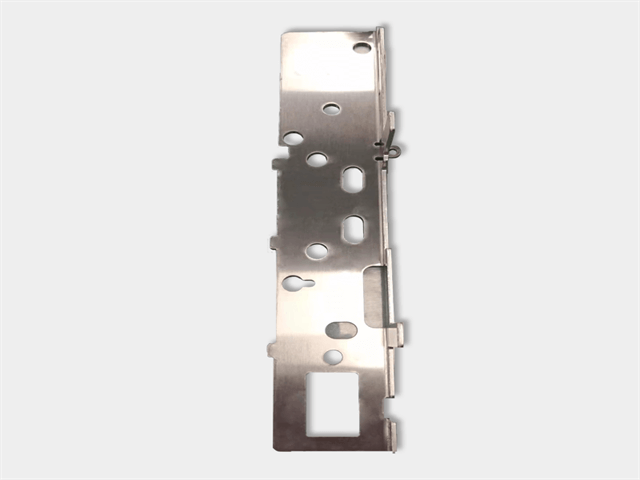

数字相机的许多部件可以使用冲压制造,包括相机机身和各种内部组件,如支架和支承。冲压可用于形成金属零件以精确的尺寸,使其成为各种相机部件的有用制造工艺。

使用金属冲压制造电机外壳具有多种优点,例如成本效益。金属冲压可以以相对较低的成本生产大量零部件,因此成为大规模生产的有吸引力的选项。此外,金属冲压允许生产精确而准确的零部件,并具有一致的质量。该过程也相对快速,因此是高产量生产的有效选项。

No matter in terms of operation technology or safety, the metal stamping process should meet the corresponding requirements, starting from its technical measures. You should know that the so-called metal stamping is a process of deforming or breaking iron, aluminum, copper and other plates and dissimilar materials to a certain shape and size by using a punch and a mold.

According to the total deformation properties of materials, hardware processing processes are divided into two categories and five types of deformation in the stamping process.

No matter where the designed and produced stamping parts are used for processing, they need to be designed and processed in strict accordance with the corresponding principles, so as to achieve energy conservation and other purposes on the premise of ensuring product quality.

if there is a slight carelessness in the operation process of stamping, it is easy to cause the metal stamping parts to crack, tear, and other undesirable phenomena, affecting the normal use of the products.

No matter where the designed and produced stamping parts are used for processing, they need to be designed and processed in strict accordance with the corresponding principles, so as to achieve energy conservation and other purposes on the premise of ensuring product quality.

_spic_spic.png)

The quality of metal stamping parts is improving, and the requirements for mold quality and service life are high. The effective way to improve the quality.

Many of the products we use in our lives are made of metal stamping parts, but friends who are engaged in metal stamping parts processing know.

_spic.png)

In fact, the metal stamping parts can be divided into two categories according to different processes, namely separation process and forming process.

_spic.png)

metal stamping dies are the most important technological equipment in the process of metal parts stamping, to prolong the service life and use the effect, it is necessary to do maintenance work on it.

_spic.png)

Metal stamping parts can be divided into two categories according to different processes, namely the separation process and the forming process.

_spic.png)

The characteristics of metal stamping parts processing are high production efficiency, product quality is stable and interchangeability is good, a high utilization rate of materials, the material does not need to be heated, the mechanical properties of punching parts are improved, and a wide range of applications.

_spic.png)

The wide application of metal stamping parts should be beyond our imagination, and it will be involved in almost every field of life. However, when you use this kind of metal stamping parts, you will always encounter some problems. No matter what the reason is, these faults of metal stamping parts must be solved in time.

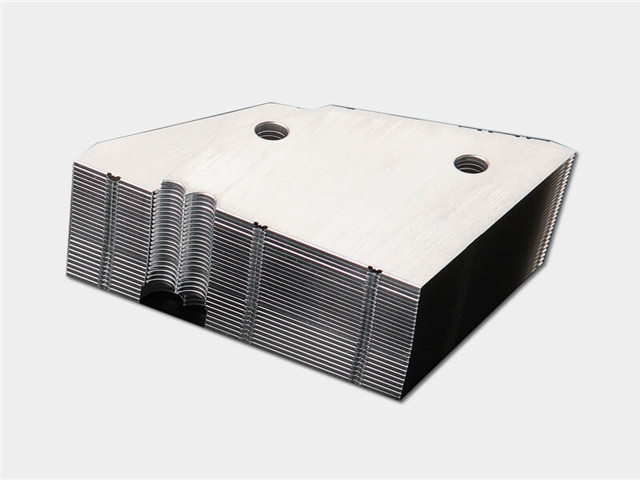

With the development of hardware products industry, the production equipment and technology of metal stamping parts are constantly improving, and the metal stamping parts are becoming more and more precise. Precision metal stamping parts can be divided into various types according to industry, use and process characteristics.

The processing of precision metal stamping is no longer a fashionable thing. People in the industry know that the process is the same, and it is inseparable from it. However, with the upgrading of technology, its advantages will be greatly improved this time.

With the development of the hardware industry, the production equipment and technology of metal stamping parts are constantly improving, and metal stamping parts are becoming more and more precise.

This article will explain 8 purposes of machining metal stamping parts, including auto parts, electronic parts, home appliance parts, integrated circuit lead frames, Motor cores, electrical iron cores, Heat exchanger fins, and other parts.

The processing of metal stamping parts is a process that uses punches and dies to deform or break stainless steel, iron, aluminum, copper, and other plates and heterosexual materials to achieve a certain shape and size.

It can be learned from the "Modern Chinese Dictionary" that contemporary "hardware" generally refers to gold, silver, copper, iron, and tin (aluminum), these five kinds of metal utensils that are common and commonly used in our lives material.

Precision hardware processing is a process with high requirements in all aspects, but as long as these precautions are followed, it can generally be done well.

The advantages of metal stamping parts and factors affecting the accuracy of precision metal stamping parts.

In recent years, although China's metal stamping processing industry has developed a lot, it lags far behind the development of the machine tool industry. According to data, China's current annual sales of metal stamping parts are 10 billion yuan, of which the share of metal stamping hard tools is less than 25%. with a growing need.

How to adjust the machine during the production of precision metal stamping parts is the first problem that a precision metal stamping terminal factory has to face, and it is also a skill that a precision metal stamping terminal factory needs to master.

The chemical composition of the material, material surface quality, microstructure, and thickness tolerance.

Metal stamping parts are very common metal processing products in life, and they play a very important role. Let's understand the measurement method of metal stamping parts.

With the development of society, metal stamping parts have been applied to all aspects of our daily life. The requirements for stamping parts are constantly improving, and the quality requirements for precision metal stamping parts are also getting higher and higher.

With the improvement of people's living standards, the quality requirements for stamping parts are also getting higher and higher. Stamping parts processing plants should pay attention to understanding customer needs and meeting customer needs, which is the top priority.

In the past, Feng-Yu has been focusing on completing the customer's entrustment, committed to the improvement of processing technology, and accumulated its own strength.